Pon Power News

The online magazine of Pon Power, the Caterpillar dealer for diesel and gas engines and generators.

In this magazine we keep you up to date on the latest projects, new products & services and technical innovations.

FACTS & FIGURES

CLIENT

Kwekerij Zijdezicht BV, De Lier

PRODUCT

Asters and chrysanthemums

INSTALLATION

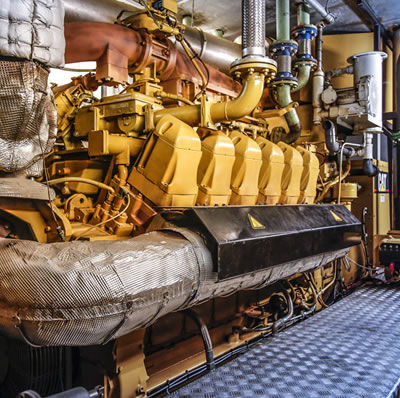

Cat 3512E and Cat 3516A Combined Heat Power plants (CHP)

CHP PLANT

Gas fired heating system generating heat and electricity. Widely used in the glasshouse industry which utilizes CO2 flue gases as a gaseous fertilizer

RELEVANT LEGISLATION

Directive Medium Size Combustion Plants (formerly BEMS)

APPLIES TO

CHP plants under 50 mWh and over 130 kWh

HP SYSTEM RECONDITIONED AND ADAPTED TO FUTURE EMISSION REQUIREMENTS

TAILOR-MADE SOLUTION TO PREPARE GROWER FOR FUTURE

ASK A QUESTION

FACTS & FIGURES

APPLIES TO

RELEVANT LEGISLATION

CHP PLANT

INSTALLATION

PRODUCT

CLIENT

CHP plants under 50 mWh and over 130 kWh

Directive Medium Size Combustion Plants (formerly BEMS)

Gas fired heating system generating heat and electricity. Widely used in the glasshouse industry which utilizes CO2 flue gases as a gaseous fertilizer

Cat 3512E and Cat 3516A Combined Heat Power plants (CHP)

Asters and chrysanthemums

Kwekerij Zijdezicht BV, De Lier

FACTS & FIGURES

COMPLETE REVISION

From the discussions with John Krijger it was concluded that the existing installation still perfectly matched the situation and the wishes of the grower. However, being 10 years old, it was no longer equipped to meet the new legislation with respect to CO2 emissions, taking effect 1 January 2017. Therefore, it was decided to fully recondition the installation, and, in the process, install a Combustion Kit. The Combustion Kit is a Pon Power developed solution for reducing methane sludge, which, when installed, allows the installation to operate in compliance with future emission requirements. Explains Krijger: “We had a fairly tight timeline to get the work done, leaving no leeway for error or any form of flexibility. The technicians of Pon Power set to work with three men on site and finished the task in three weeks. It all came together beautifully, perfectly timed, and within budget. The revamped installation is now up and running like clockwork.” Patrick de Ruiter is a satisfied man: “These things can be a puzzle, but we always manage a solution that suits the client best. That’s how we work in Pon Power. And it’s a pretty good feeling when you can pull it off, again.”

A Cat 3516A CHP plant was installed at the location of Zijdezicht at the Gildelaan. The installation was built in 2006 and had run nearly 50,000 hours since then.

John Krijger, managing director of Kwekerij Zijdezicht: “In those ten years, we’d seen very few problems with the installation. We had a 24/7 service contract with Pon Power, which included monitoring. They would pick up a potential problem even before we were aware of it.” So, when the installation had come close to 50,000 running hours, – the point at which a decision had to be made either to recondition or replace the system – Pon Power was

first in line. Krijger: “A year and a half ago, they reconditioned our other Cat CHP plant and that went without a hitch. We were very happy with the service, and were looking to work out a deal with them for this job as well. Fortunately, we could agree on a proposition without too much fuss.” Patrick de Ruiter, Account manager Service at Pon Power, clarifies: “We sat down with John and looked at the situation from his perspective. What exactly did he need? What would be the best solution in his situation? Once we’d mapped those questions, we were able to offer a tailor-made solution that not only was the most economic, but would deliver an installation that prepared his business operations for years into the future.”

Patrick de Ruiter

Accountmanager Service, Pon Power

“These things can be a puzzle, but we always manage a solution that suits the client best.”

EMISSION REQUIREMENTS

ADAPTED TO FUTURE

HP SYSTEM RECONDITIONED AND

FOR FUTURE

PREPARE GROWER

SOLUTION TO

TAILOR-MADE

Kwekerij Zijdezicht is a glasshouse industry that specializes in the breeding and cultivation of asters and chrysanthemums. At three locations, covering some 71,000 sqm., Zijdezicht uses the most advanced technologies in order to produce the best flowers, with the least possible environmental impact. For this reason, Zijdezicht uses Cat CHP plants at two of its locations to optimize the required energy supply for heat, light and CO2. The remaining CO2 requirement is obtained from OCAP, a supplier of residual CO2 from producers such as Shell, thus preventing rest emissions from being released into the environment.