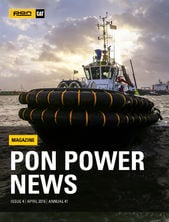

Pon Power News

The online magazine of Pon Power, the Caterpillar dealer for diesel and gas engines and generators.

In this magazine we keep you up to date on the latest projects, new products & services and technical innovations.

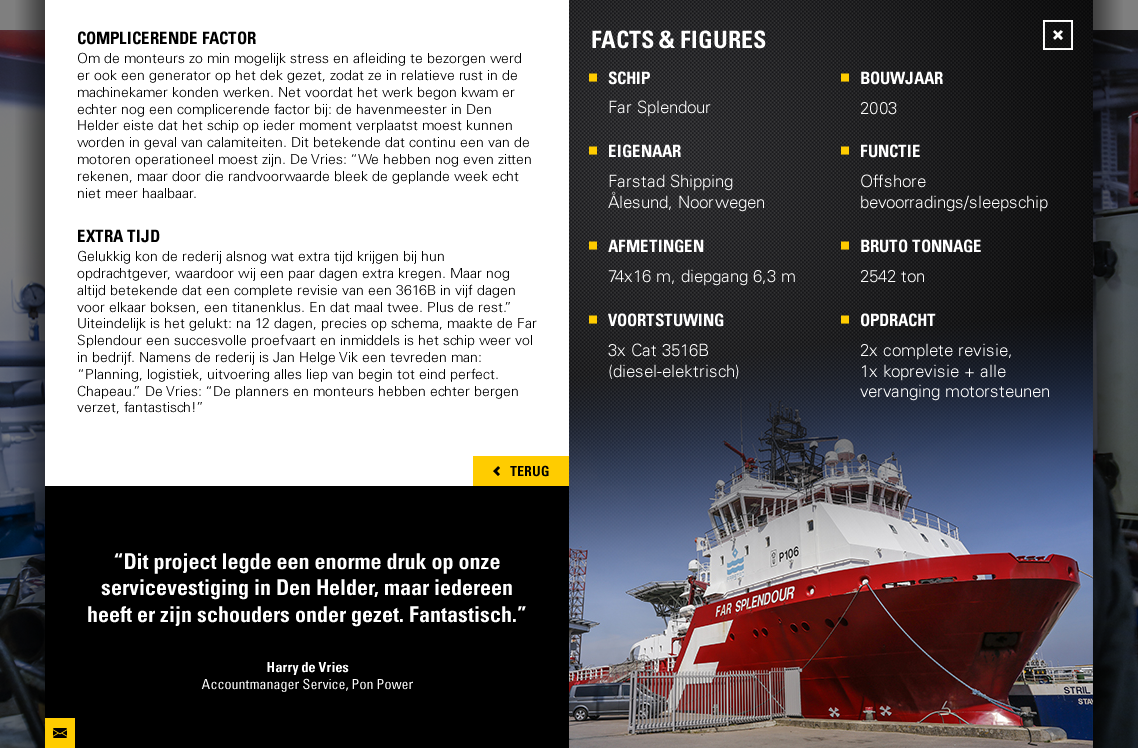

FACTS & FIGURES

SHIP

Far Splendour

YEAR OF CONSTUCTION

2003

OWNER

Farstad Shipping Ålesund, Norway

FUNCTION

Offshore provisioning / towing

DIMENSIONS

74 x 16 m, draught 6.3 m

GROSS TONNAGE

2,542 ton

PROPULSION

3 x Cat 3516B (diesel-electrical)

PROJECT

2 x complete overhaul,

1 x cylinder head reconditioning + replace all engine mounts

MONSTER JOB FAR SPLENDOUR DONE IN RECORD TIME.

“UH ... CAN WE DO THIS IN A WEEK?!”

ASK A QUESTION

FACTS & FIGURES

PROJECT

PROPULSION

GROSS TONNAGE

DIMENSIONS

FUNCTION

OWNER

YEAR OF CONSTUCTION

SHIP

2x complete overhaul,

1x cylinder head reconditioning + replace all engine mounts

3 x Cat 3516B

(diesel-electrical)

2,542 ton

74x16 m, draught 6.3 m

Offshore provisioning / towing

Farstad Shipping

Ålesund, Norway

2003

Far Splendour

FACTS & FIGURES

Harry de Vries

Accountmanager Service, Pon Power

“This project put a lot of pressure on our service branch in Den Helder, but everyone put their shoulders to it. Fantastic.”

COMPLICATING FACTOR

To relieve the mechanics as much as possible of stress and distraction, a generator was placed on deck so that the work in the engine room could be done in relative peace and quiet. Then, as the work was about to be started, another complicating factor reared its head: the Harbour Master of Den Helder insisted that the ship must be able to be moved, at any time, in the event of a calamity. This meant that at least one engine had to be operational. De Vries: “We tried figuring even that one out, but it proved a bridge too far; there was no way we could make it fit within the planned week.

EXTRA TIME

Fortunately the client was able to negotiate some extra time from their principal, and that gave us a few more days. But, it didn’t change the fact that performing a complete overhaul on a 3616B, in just five days, was a very, very considerable task. And then multiply that by two. Plus the rest.” Still, it all came together in the end: 12 days later, right on schedule, Far Splendour completed a successful test ride and the ship is now fully operational again. Speaking for his company, Jan Helge Vik is a satisfied man: “Planning, logistics, execution, all perfect, start to finish. Hat off.” Notes De Vries: “Those planners and mechanics really moved mountains. Fabulous!”

Jan Helge Vik

Marine Superintendent, Farstad Shipping

“Two complete overhauls, a cylinder head reconditioning, and various other works, all finished in a short time, in a very small engine room. Commendable!”

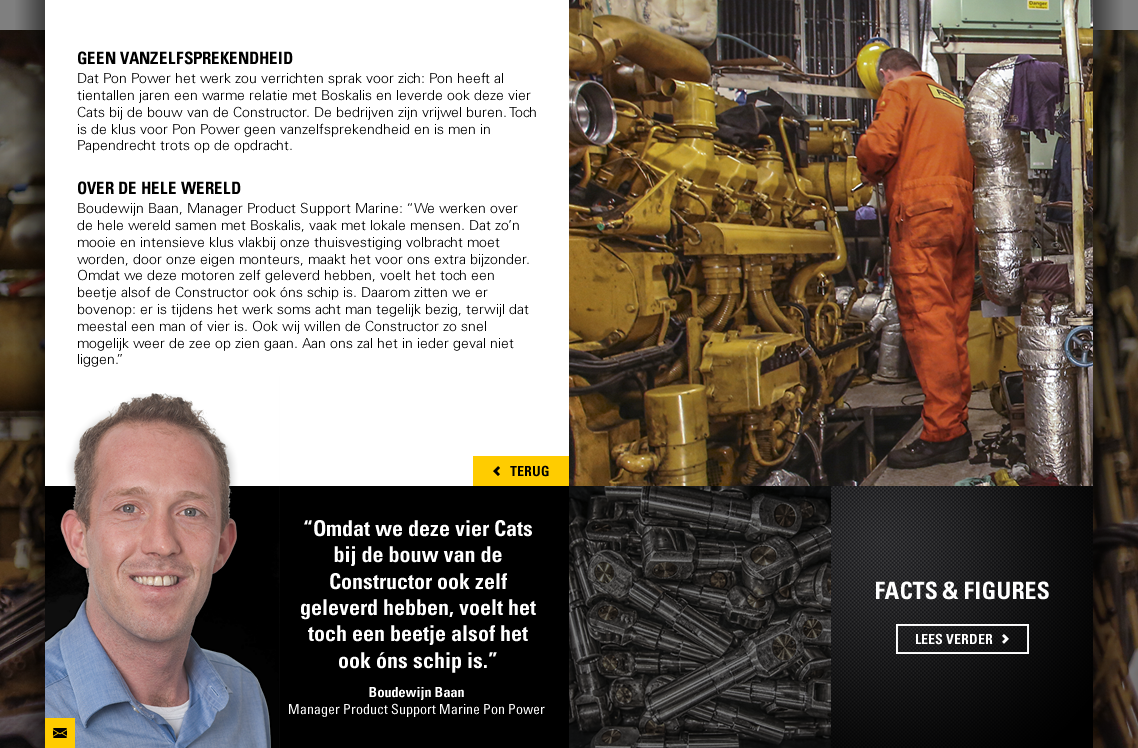

LOGISTIC CHALLENGES

“There were several ‘interesting’ preconditions attached to this project”, says Harry de Vries, Account manager Service at Pon Power, subtly understating the challenge. “Because the shipping company had received an unexpected order they couldn’t refuse, the scheduled two overhauls- a cylinder head reconditioning and replacement of engine mounts- had to be completed within a week.” Clarification: the standard time frame for a complete 3515B overhaul is about three weeks. Add to this the fact that the ship’s engine room was relatively small, and that other work needed to be performed by Farstad itself, and you have some idea of the planning and logistic challenges at hand.

However, seeing that Pon Power had negotiated with this client for some time, the mechanics at the service branch in Den Helder decided they would deal with it, despite the pressures of time. Jan Helge Vik, Marine Superintendent at Farstad Shipping: “A solution was provided by placing three containers filled with parts and tools on deck prior to the work. This made it possible for the mechanics to work continuously in 12–hour shifts, with two men working on each engine, day and night.”

In a service oriented organization, it’s not unusual to be asked if a project can be completed sooner than normally allowed for. But when the Norwegian Farstad Shipping Company needed to claim back two-thirds of the time allocated for work scheduled on its ship the Far Splendour, even Pon Power blinked. A tale of pushing and squeezing, with a lot of sweat in between.

ENGINE CONDITION

DONE IN RECORD TIME.

MONSTER JOB FAR SPLENDOUR

THIS IN A WEEK?!”

“UH ... CAN WE DO