Pon Power News

The online magazine of Pon Power, the Caterpillar dealer for diesel and gas engines and generators.

In this magazine we keep you up to date on the latest projects, new products & services and technical innovations.

FACTS & FIGURES

PRODUCT LINK

Hardware that is linked to the board computer of an engine. Via a link the system transmits data, thus making it possible to monitor engine performance.

EMSERVICES

Equipment Management Services: the service Pon Power is able to deliver on the basis of various technologies such as Product Link. These services are designed to achieve lower operational costs for the customer.

APM TERMINALS

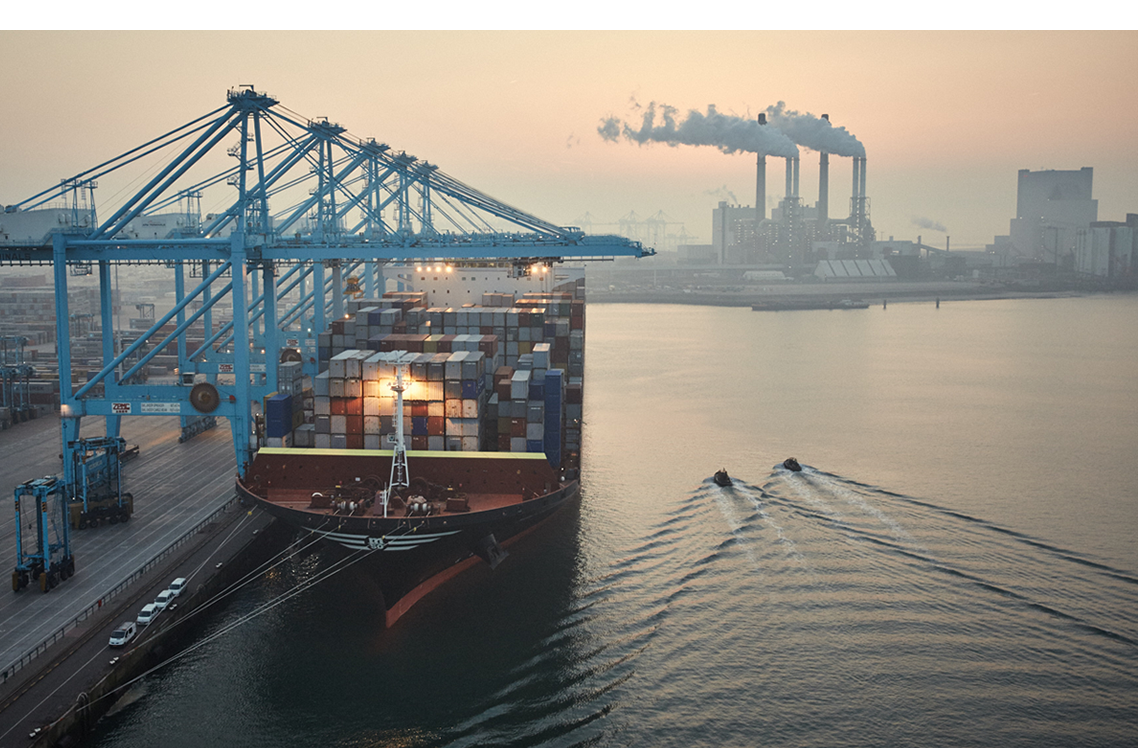

Worldwide operating network of port and terminal facilities, located at Maasvlakte (NL)

“I am now able to monitor that engine very specifically and effectively, and, in the future, will do the same for an entire fleet of engines.”

PRODUCT LINK PILOT GOING WELL

ASK A QUESTION

FACTS & FIGURES

APM TERMINALS

EMSERVICES

PRODUCT LINK

Worldwide operating network of port and terminal facilities, located at Maasvlakte (NL)

Equipment Management Services: the service Pon Power is able to deliver on the basis of various technologies such as Product Link. These services are designed to achieve lower operational costs for the customer.

Hardware that is linked to the board computer of an engine. Via a link the system transmits data, thus making it possible to monitor engine performance.

FACTS & FIGURES

Jos Bosman

Damage & Warranty Coordinator

APM Terminals Rotterdam

“I am now able to monitor that engine very specifically and effectively, and, in the future, will do the same for an entire fleet of engines.”

CAT CONNECT

Management Trainee Alexander Hemmes is one of the people responsible for the rollout of EMServices in Pon power. He explains: “This service is part of Caterpillar’s umbrella strategy, named Cat Connect. That strategy hinges on the collection of data, and on that basis, provide customers with a better service. EMServices is the first such service under the Cat Connect strategy, and the pilot so far has been very successful. By running pilots at various customers we have been able to test if all the data obtained from the engines is properly received and that is being translated effectively into user-friendly infographics. And all of that appears to be happening.” Does that mean Product Link is now readily available for customers from Pon Power? Or, that it is now supplied as a standard feature on every newly installed engine? According to Hemmes, that is where the system is headed, although some further development work is necessary: “We are now ready for the final development of the system with a select group of customers, working closely with Caterpillar. In this stage, our goal is to develop new services that will enable us to support and advise customers even more proactively. And, yes, we would like to be able to offer this system to all our customers, so we’re doing all we can to make that happen. Your patience is appreciated!”

Alexander Hemmes

Management Trainee Pon Power

“What’s special about CatConnect is that it will enable us, in future, to really assist and advise customers proactively. And it’s only getting better.”

STRADDLE CARRIER

APM Terminals operates port and terminal facilities in 69 countries on five continents. In the Netherlands, APM is active as a container terminal operator on the Maasvlakte in Rotterdam. The Product Link system was installed there, several months ago, on the Cat C13 engine of a ‘Straddle Carrier’, also known as a mobile container lift. Jos Bosman, Damage & Warranty Coordinator at APM Terminals Rotterdam, explains: “A Straddle Carrier is a 60 ton, 12.5 meter high, driving crane. It looks a lot like a boat lift. We use it to lift containers and bring them wherever they need to go. Since the engine of this particular Straddle Carrier has been connected to the Product Link system, my asset management has become very effective. When there is a problem or failure, I receive an email or phone call from the control room at Pon, and we are then able to take immediate action as required.”

But, Product Link is more than simply a troubleshooting tool: via a convenient, user friendly online dashboard, the system provides relevant information on matters such as fuel consumption, loading, running hours, wear, and so on. Bosman: “This is very helpful, as we are looking to use Product Link for our conditional based monitoring program, which enables us to move proactively on the basis of the generated data and analyses. It is a form of monitoring which assist us in planning and performing correct – and as needed, adjusted – preventive maintenance.”

As in, for example, the auto industry (Connected Car) it is becoming increasingly simple, thanks to new technologies, to remotely-monitor engines, machinery and other equipment in other industries also. It has made fine-tuning and preventative maintenance much simpler, while increasing the efficiency and life span of valuable assets. Some time ago, Motor News posted a feature on Product Link, the Caterpillar solution for remote monitoring. Currently this system is being tested at five Pon Power customers, in different sectors of industry. We tested the waters with a pilot at APM Terminals Rotterdam on the Maasvlakte.

PILOT

WELL

PILOT GOING

PRODUCT LINK