Complete, ex-factory-certified system helps ship owners and captains to work more sustainably

Daan de Jong

We have the ultimate retrofit IMO III solution for future-oriented entrepreneurs

For which engines is the system available?

What does the whole system consist of?

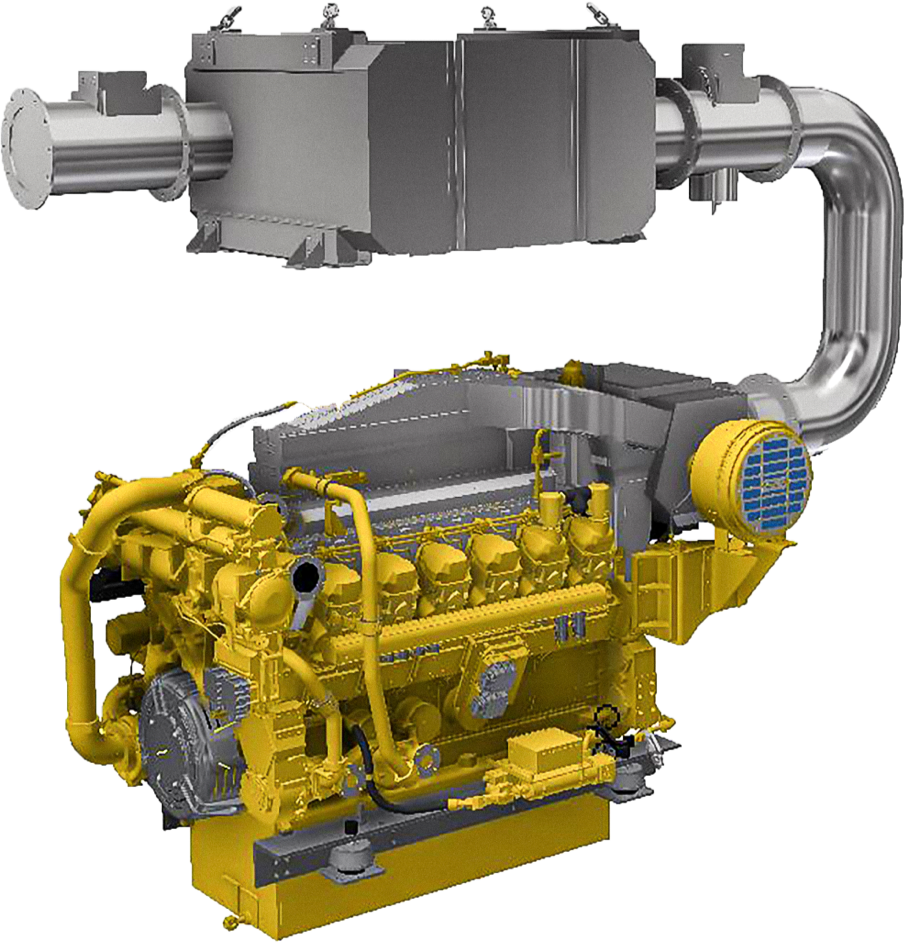

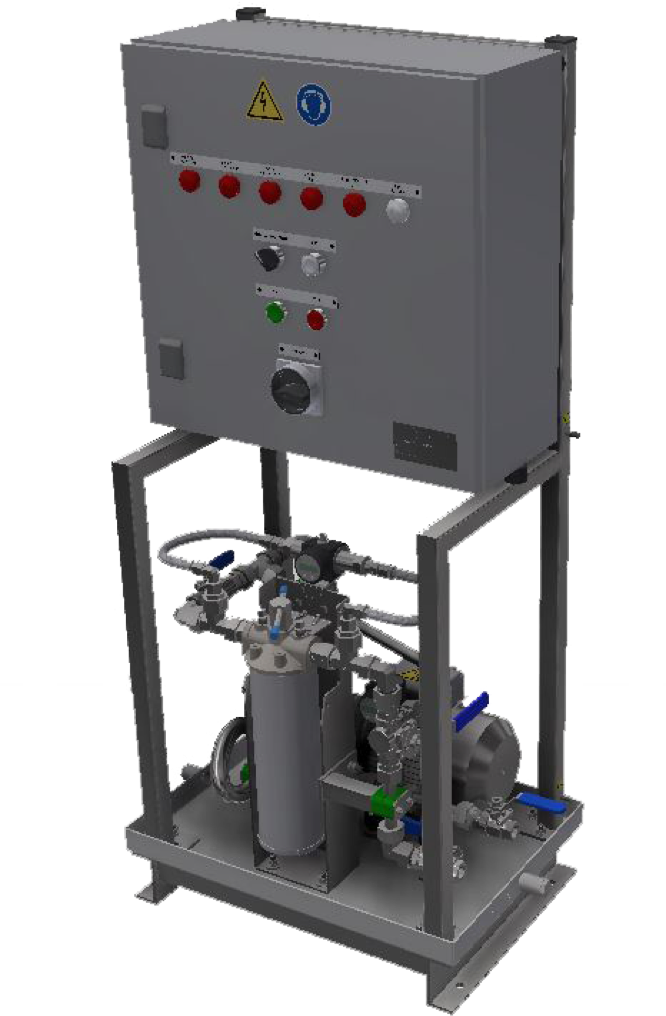

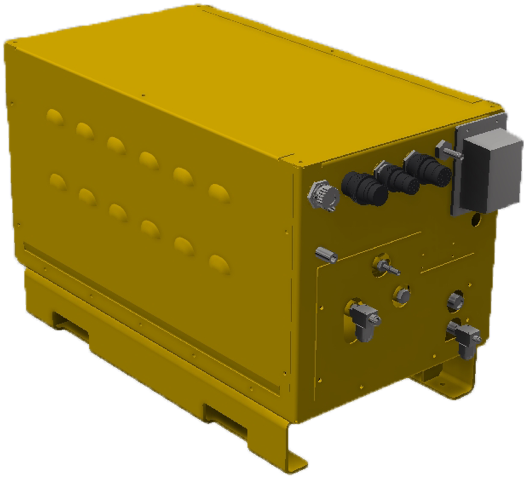

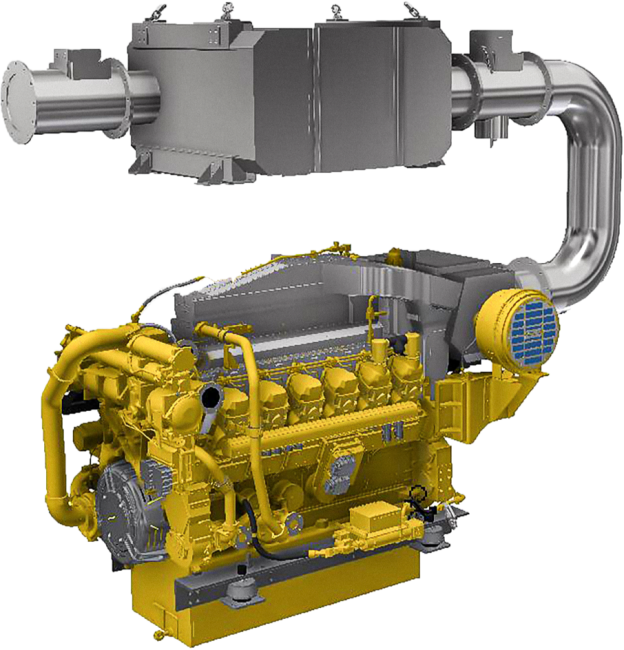

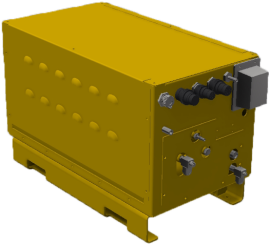

It consists of the SCR itself and also a urea tank, pipes, a urea dosing unit and a urea transfer pump. All in all, it is quite a considerable system, which can produce an interesting puzzle in tight engine rooms. Technical drawings of the system are available, so that interested entrepreneurs can to some extent do their own fitting and measuring. Of course, our Pon Power team is also ready with advice and know-how to get the retrofit completed. That approach is a proven success. The result is that you can sail for a longer period of time with the same engine while also reducing your environmental impact. And as with all Cat OEM products, you enjoy the security of the Pon Power/Caterpillar service network. A win-win situation.

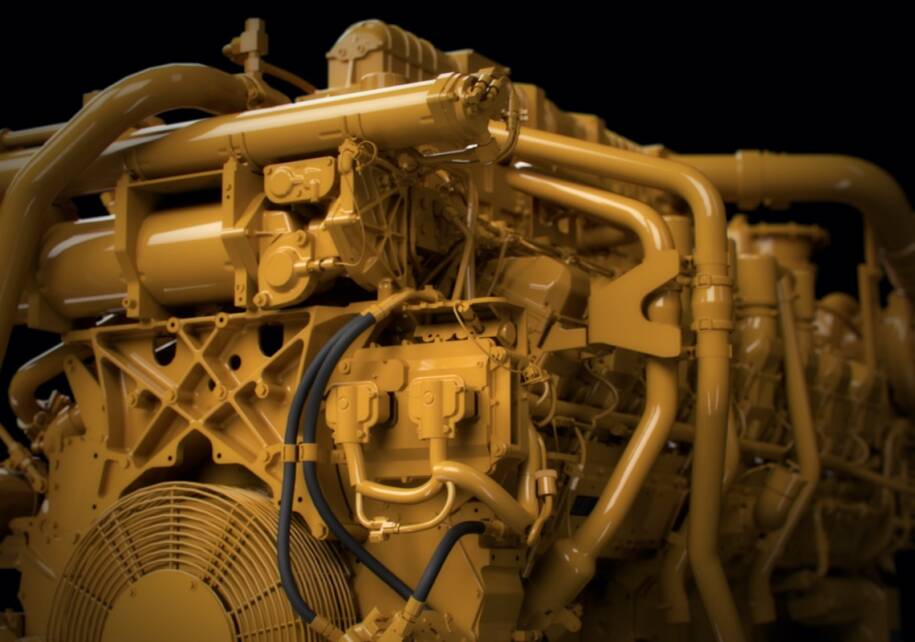

Largely for the existing Cat engines that already comply with IMO II. A full list of engines can be found here.

Engine list

read more about the retrofit IMO III

Why is this system necessary? Isn't it easier to meet the stricter requirements through better engine management?

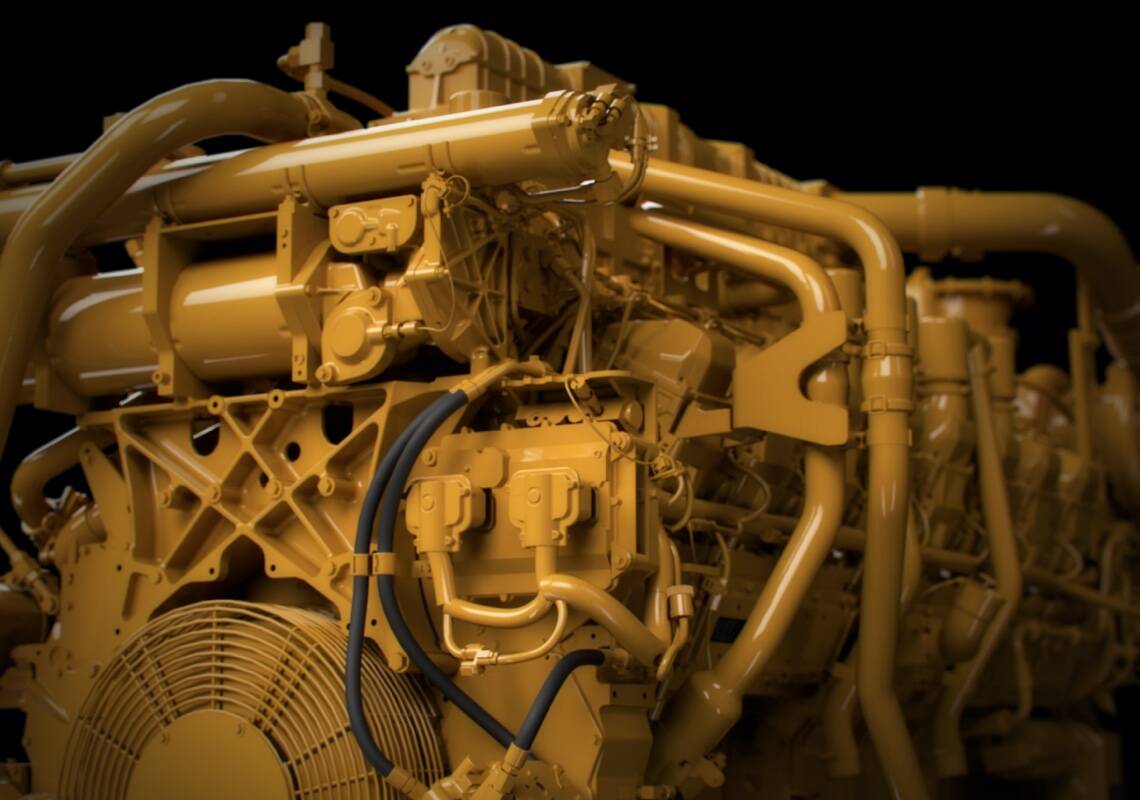

When the IMO II legislation came into effect in 2011, it was still possible to adjust engine management in such a way that you could meet those stricter requirements. For IMO III, the emission requirement for NOx is so strict that it can no longer be solved with engine management. So an additional after-treatment system, the SCR, must be added.

What exactly is an SCR?

A Selective Catalystic Reduction system is an extra component through which exhaust gases from the engine are passed. Urea is added to those gases. In combination with catalytic elements, they cause a chemical reaction that converts NOx into harmless substances. It's similar to AdBlue for trucks.

What does that solution consist of?

We can add a retrofit SCR system to a wide range of existing IMO II Cat engines. This allows these captains and shipowners to immediately comply with the stricter IMO III requirements, including certification. Caterpillar distinguishes itself as an engine manufacturer by being able to supply an SCR ex-factory, including full IMO III certification. So there is no need for an external inspection body to look into it. In addition, this certification method also ensures that the system no longer needs to be periodically inspected, which results in considerable cost savings.

Daan de Jong

Manager Sales Marine, Pon Power

“Of course, our Pon Power team is also ready with advice and know-how to get the retrofit completed”

Daan, tell us about IMO III

With effect from 2021, new ships with keel laying must meet IMO III emission requirements. However, many clients, ports, governments and energy suppliers require that ships already comply with IMO III or do so from 1 January, but the vast majority of existing ships do not comply with this. In addition, some entrepreneurs do not want to wait for a new ship, but already want to set a good example and make their business operations greener. Cat has developed a great solution for all these situations.

It is well known that from 1 January 2021, newly built ships with keel laying must comply with the new, stricter IMO III emission requirements. But for captains and ship owners who want to achieve their sustainability goals by making their existing Cat engines IMO III-certified, Caterpillar offers a complete and certified retrofit solution. We asked Daan de Jong, Marine Sales Manager at Pon Power, about the ins and outs of this progressive solution.

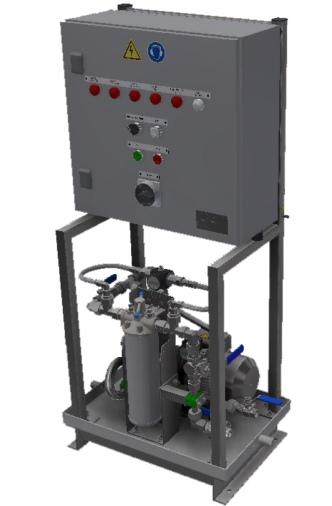

Ureum transfer pump

Ureum dosing unit

We have the ultimate retrofit IMO III solution for future-oriented entrepreneurs

Complete, ex-factory-certified system helps ship owners and captains to work more sustainably

Daan de Jong

Why is this system necessary? Isn't it easier to meet the stricter requirements through better engine management?

When the IMO II legislation came into effect in 2011, it was still possible to adjust engine management in such a way that you could meet those stricter requirements. For IMO III, the emission requirement for NOx is so strict that it can no longer be solved with engine management. So an additional after-treatment system, the SCR, must be added.

What does the whole system consist of?

It consists of the SCR itself and also a urea tank, pipes, a urea dosing unit and a urea transfer pump. All in all, it is quite a considerable system, which can produce an interesting puzzle in tight engine rooms. Technical drawings of the system are available, so that interested entrepreneurs can to some extent do their own fitting and measuring. Of course, our Pon Power team is also ready with advice and know-how to get the retrofit completed. That approach is a proven success. The result is that you can sail for a longer period of time with the same engine while also reducing your environmental impact. And as with all Cat OEM products, you enjoy the security of the Pon Power/Caterpillar service network. A win-win situation.

Daan, tell us about IMO III

With effect from 2021, new ships with keel laying must meet IMO III emission requirements. However, many clients, ports, governments and energy suppliers require that ships already comply with IMO III or do so from 1 January, but the vast majority of existing ships do not comply with this. In addition, some entrepreneurs do not want to wait for a new ship, but already want to set a good example and make their business operations greener. Cat has developed a great solution for all these situations.

It is well known that from 1 January 2021, newly built ships with keel laying must comply with the new, stricter IMO III emission requirements. But for captains and ship owners who want to achieve their sustainability goals by making their existing Cat engines IMO III-certified, Caterpillar offers a complete and certified retrofit solution. We asked Daan de Jong, Marine Sales Manager at Pon Power, about the ins and outs of this progressive solution.

Daan de Jong

Manager Sales Marine, Pon Power

“Of course, our Pon Power team is also ready with advice and know-how to get the retrofit completed”

We can add a retrofit SCR system to a wide range of existing IMO II Cat engines. This allows these captains and shipowners to immediately comply with the stricter IMO III requirements, including certification. Caterpillar distinguishes itself as an engine manufacturer by being able to supply an SCR ex-factory, including full IMO III certification. So there is no need for an external inspection body to look into it. In addition, this certification method also ensures that the system no longer needs to be periodically inspected, which results in considerable cost savings.

What does that solution consist of?

What exactly is an SCR?

A Selective Catalystic Reduction system is an extra component through which exhaust gases from the engine are passed. Urea is added to those gases. In combination with catalytic elements, they cause a chemical reaction that converts NOx into harmless substances. It's similar to AdBlue for trucks.

Ureum transfer pump

Ureum dosing unit

read more about the retrofit IMO III

For which engines is the system available?

Largely for the existing Cat engines that already comply with IMO II. A full list of engines can be found here.

Engine list