“The standard choice used to be a diesel engine, but new combinations of solutions provide far more choices”

SUSTAINABLE COMBUSTION ENGINES THROUGH ALTERNATIVE FUELS

JOOST SCHAPENDONK

Are there any other important developments at this moment?

Absolutely. We are seeing the introduction of all types of new energy converters and storage possibilities in the market. Think batteries, fuel cells and combinations of these with combustion engines, in other words hybrid systems. The standard choice used to be a diesel engine, but new combinations of solutions provide far more choices. That is where we see many opportunities. It is with good reason that we within Pon Power recently created the Power & Propulsion Solutions division. This team focuses exclusively on the development of this type of new and innovative energy solutions. That way, we prepare for an uncertain but very exciting future. In the next edition of Motorennieuws, we will tell you more about this new division.

And ammonia?

As far as we are concerned, ammonia isn’t really interesting, because the flame speed is so low that it is practically useless in the high-speed engines that we sell. Another thing is that its toxicity is often underestimated. What you find in somebody’s cleaning cupboard is a product containing 3% ammonia, but to use it as fuel it would have to be 100%, pure ammonia. A few drops in the engine room could be fatal and requires total evacuation. That is a serious extra challenge and therefore not a realistic option for us at the moment.

It often seems that hydrogen is seen as the Holy Grail in the market. What are your thoughts about this?

Hydrogen has undeniable potential, but mainly on land. As I said before, storage of sufficient hydrogen on ships is often still problematic. For gas engines on land, there is an increasing number of options to add a percentage of hydrogen to the fuel. Hydrogen is carbon free, so if you burn it, you will not produce CO2. That is how you reduce the emissions . If we want to move towards higher percentages, then we must make technical changes to the engines. Moreover, the production of green hydrogen is still limited at present. That is why as far as we are concerned, hydrogen is not a fully fledged alternative yet, but in future we can certainly see it as a useful fuel for applications on land.

An encouraging development, but still some way off. Is there already something that works as a substitute for diesel or gas?

That is HVO, Hydrotreated Vegetal Oil. In common parlance, it is also known as ‘blue diesel’. HVO is a second-generation biofuel. It is essentially a drop-in replacement for fossil diesel. HVO is available and works well but at this moment the price remains an obstacle for many companies. The product’s availability is limited, which cranks up the price. Moreover, it is made of biological matter, the availability of which is relatively limited. HVO can be used without any significant modifications to the engine. Readers of this article who wish to change to HVO need to know a few minor but important things. If they contact us, we are happy to explain what they must bear in mind.

What are the benefits of methanol?

The key benefit is that methanol lends itself particularly well to use in a combustion engine. It hasn’t got as much energy content as diesel, but more than the other alternatives. Moreover, it is possible to make a renewable, green variant of it. There are different ways to achieve that, for example using biological waste products such as domestic waste, residual products and by-products from the paper industry or biomass. However, the most ideal variant has been made of green hydrogen, with CO2 from the atmosphere or industrial processes which you then combine to form green methanol. You still have CO2 emissions, but you are reusing it, so there are no new emissions. Local emissions, such as soot, particulate matter and SOx are close to zero. Green methanol is therefore a pleasing alternative particularly in ports and built-up areas. By way of proof of concept we as Pon Power had a Cat engine run on methanol last year. That was a great success. The concept was not intended for market introduction, but it helped us improve our understanding of how it works and which challenges still remain.

What is the status of the alternative fuels? Is there already something that is suitable for large-scale application in Cat engines?

As nearly all parties that are grappling with this problem in a serious way, one day you just line up all the various alternatives. And you start assessing all facets, and determine the pros and cons. Think of safety, costs, bunker and storage possibilities, range etcetera. That isn’t a question of good or bad, or of whether hydrogen is better or worse than methanol, for example, but it is about what is most feasible and realistic. We believe that methanol has the best chances of coming out on top for maritime applications. Not so much from an engine technology point of view, but more because carrying hydrogen in sufficient amounts for many applications is currently presenting too many challenges for shipping, at any rate with the technology presently available. With today’s information, we think that we can sell methanol engines three years from now. However, we hope we will be able to conduct experiments on board for customers before that time.

What is the biggest challenge in this area?

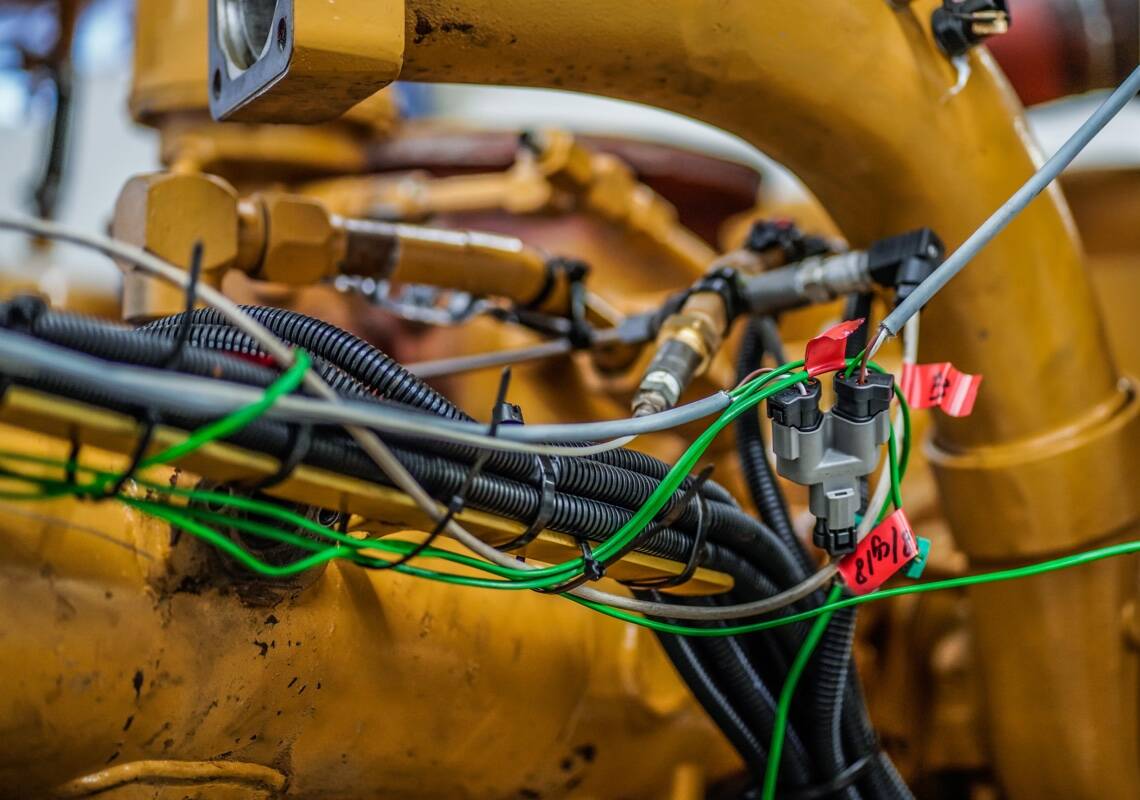

It took us 100 years to improve diesel engine technology to what it is now. Today’s diesel engines are the result of a century of attempts to perfect them. Now we are faced with the task of converting these engines in a very short time and make them suitable for alternative fuels. If we had started that process with a blank sheet of paper and with 20 years of time, we would probably have built a completely different engine. The fact that our starting point is a diesel engine makes this a technically daunting task. However, the good news is that almost every modern Cat engine is expected to be capable of being modified so that it suitable for alternative fuels.

Joost, how far up the Pon Power list of priorities is sustainability?

The energy transition is one of the most important topics we are working on, if not the most important one. On the one hand, we are developing new energy solutions, such as Cat Solar, and on the other hand we are looking for ways to make our combustion engines more sustainable. A lot of work is happening in close cooperation with Caterpillar, particularly because everything needs to be certified.

JOOST SCHAPENDONK

Director Marketing & Technology, Pon Power

Together with Caterpillar, we at Pon Power have been leading the way for years with respect to increasing sustainability in the industries in which we are active with our solutions. The energy transition is a global challenge in which developments follow each other at a rapid pace. As more and more alternatives for fossil fuels become available, this is a great moment for an update. Motorennieuws asked Joost Schapendonk, Marketing & Technology Director at Pon Power, about the state of affairs.

JOOST SCHAPENDONK

“The standard choice used to be a diesel engine, but new combinations of solutions provide far more choices”

SUSTAINABLE COMBUSTION ENGINES THROUGH ALTERNATIVE FUELS

Together with Caterpillar, we at Pon Power have been leading the way for years with respect to increasing sustainability in the industries in which we are active with our solutions. The energy transition is a global challenge in which developments follow each other at a rapid pace. As more and more alternatives for fossil fuels become available, this is a great moment for an update. Motorennieuws asked Joost Schapendonk, Marketing & Technology Director at Pon Power, about the state of affairs.

What is the biggest challenge in this area?

It took us 100 years to improve diesel engine technology to what it is now. Today’s diesel engines are the result of a century of attempts to perfect them. Now we are faced with the task of converting these engines in a very short time and make them suitable for alternative fuels. If we had started that process with a blank sheet of paper and with 20 years of time, we would probably have built a completely different engine. The fact that our starting point is a diesel engine makes this a technically daunting task. However, the good news is that almost every modern Cat engine is expected to be capable of being modified so that it suitable for alternative fuels.

What are the benefits of methanol?

The key benefit is that methanol lends itself particularly well to use in a combustion engine. It hasn’t got as much energy content as diesel, but more than the other alternatives. Moreover, it is possible to make a renewable, green variant of it. There are different ways to achieve that, for example using biological waste products such as domestic waste, residual products and by-products from the paper industry or biomass. However, the most ideal variant has been made of green hydrogen, with CO2 from the atmosphere or industrial processes which you then combine to form green methanol. You still have CO2 emissions, but you are reusing it, so there are no new emissions. Local emissions, such as soot, particulate matter and SOx are close to zero. Green methanol is therefore a pleasing alternative particularly in ports and built-up areas. By way of proof of concept we as Pon Power had a Cat engine run on methanol last year. That was a great success. The concept was not intended for market introduction, but it helped us improve our understanding of how it works and which challenges still remain.

What is the status of the alternative fuels? Is there already something that is suitable for large-scale application in Cat engines?

As nearly all parties that are grappling with this problem in a serious way, one day you just line up all the various alternatives. And you start assessing all facets, and determine the pros and cons. Think of safety, costs, bunker and storage possibilities, range etcetera. That isn’t a question of good or bad, or of whether hydrogen is better or worse than methanol, for example, but it is about what is most feasible and realistic. We believe that methanol has the best chances of coming out on top for maritime applications. Not so much from an engine technology point of view, but more because carrying hydrogen in sufficient amounts for many applications is currently presenting too many challenges for shipping, at any rate with the technology presently available. With today’s information, we think that we can sell methanol engines three years from now. However, we hope we will be able to conduct experiments on board for customers before that time.

An encouraging development, but still some way off. Is there already something that works as a substitute for diesel or gas?

That is HVO, Hydrotreated Vegetal Oil. In common parlance, it is also known as ‘blue diesel’. HVO is a second-generation biofuel. It is essentially a drop-in replacement for fossil diesel. HVO is available and works well but at this moment the price remains an obstacle for many companies. The product’s availability is limited, which cranks up the price. Moreover, it is made of biological matter, the availability of which is relatively limited. HVO can be used without any significant modifications to the engine. Readers of this article who wish to change to HVO need to know a few minor but important things. If they contact us, we are happy to explain what they must bear in mind.

It often seems that hydrogen is seen as the Holy Grail in the market. What are your thoughts about this?

Hydrogen has undeniable potential, but mainly on land. As I said before, storage of sufficient hydrogen on ships is often still problematic. For gas engines on land, there is an increasing number of options to add a percentage of hydrogen to the fuel. Hydrogen is carbon free, so if you burn it, you will not produce CO2. That is how you reduce the emissions . If we want to move towards higher percentages, then we must make technical changes to the engines. Moreover, the production of green hydrogen is still limited at present. That is why as far as we are concerned, hydrogen is not a fully fledged alternative yet, but in future we can certainly see it as a useful fuel for applications on land.

JOOST SCHAPENDONK

Director Marketing & Technology, Pon Power

Joost, how far up the Pon Power list of priorities is sustainability?

The energy transition is one of the most important topics we are working on, if not the most important one. On the one hand, we are developing new energy solutions, such as Cat Solar, and on the other hand we are looking for ways to make our combustion engines more sustainable. A lot of work is happening in close cooperation with Caterpillar, particularly because everything needs to be certified.

And ammonia?

As far as we are concerned, ammonia isn’t really interesting, because the flame speed is so low that it is practically useless in the high-speed engines that we sell. Another thing is that its toxicity is often underestimated. What you find in somebody’s cleaning cupboard is a product containing 3% ammonia, but to use it as fuel it would have to be 100%, pure ammonia. A few drops in the engine room could be fatal and requires total evacuation. That is a serious extra challenge and therefore not a realistic option for us at the moment.

Are there any other important developments at this moment?

Absolutely. We are seeing the introduction of all types of new energy converters and storage possibilities in the market. Think batteries, fuel cells and combinations of these with combustion engines, in other words hybrid systems. The standard choice used to be a diesel engine, but new combinations of solutions provide far more choices. That is where we see many opportunities. It is with good reason that we within Pon Power recently created the Power & Propulsion Solutions division. This team focuses exclusively on the development of this type of new and innovative energy solutions. That way, we prepare for an uncertain but very exciting future. In the next edition of Motorennieuws, we will tell you more about this new division.